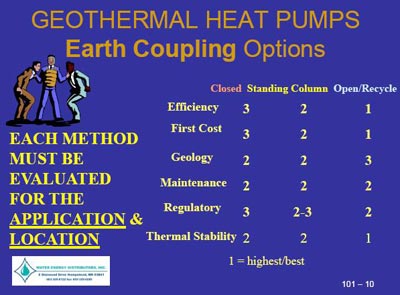

Comparison of Methods

EFFICIENCY

The Open/Recycling system takes constant temperature water, typically  50°F in New England, from the earth, reducing the return water temperature typically by 8°F in winter and typically increasing by 10°F in summer. As the source/sink water temperate remains unchanged throughout the year, this provides the highest efficiency of the three methods.

50°F in New England, from the earth, reducing the return water temperature typically by 8°F in winter and typically increasing by 10°F in summer. As the source/sink water temperate remains unchanged throughout the year, this provides the highest efficiency of the three methods.

The Standing Column winter temperature is designed around a minimum of 45°F , entering water temperature (EWT) in winter and 60°F in summer (residential).

Closed loops are designed around 32°F, EWT in winter (with antifreeze solution) and 77°F in summer. We only condone food-grad propylene-glycol as the antifreeze solution of choice.

Third party efficiency evaluations have been performed by the Air Conditioning and Refrigeration Institute (ARI 325 & 330) and more recently by the International standards Organization (ISO). ISO 13256 standards are somewhat more conservative than the more dated ARI standards.

FIRST COST

Most often, the Open/Recycle method is realized in areas where there is abundant nearsurface water. Wells are not deep and pumping is achieved with modest pumping costs. If employed return wells are generally similar shallow depths and slightly larger, but also at low costs. Open wells are often in “unconsolidated” aquifers, loose gravel and sand, and require steel or plastic casing to maintain bore hole integrity. Casing is typically required in “overburden” and terminal moraine (where the glacier stopped) – SW Massachusetts, Cape cod, Long Island and Brooklyn are examples of deep moraine.

Standing Column Wells are employed when there is near-surface bedrock and require depths of 50 –100 feet of water column per ton (12,000 btu/hr) of heating of cooling requirement. (The typical home maybe in the 3 to 5 ton range). Well depths are deeper, consequent costs are higher. However, the cost of a return or diffusion well is not required as the return water to the earth is returned back to the same borehole. Typically, domestic water needs are met by the same well. This can positively effect “first cost” as the well can provide for both needs.

Closed loops are the most costly as bore depths are typically 150-200 linear feet of bore per ton for a heating dominated geothermal application (vertical application). For a cooling dominated, typical of a very large home or commercial, bore depths are in the 220 – 280 linear feet of bore per ton. Horizontal loops, including slinky, straight horizontal, and pond applications typically require 1,000ft or more of pipe per ton.

GEOLOGY

An Open to Earth recycling system requires large amount of water and a responsible return of the water to the earth where its energy is renewed by solar contribution. (Every 55 days, the waters of the earth absorb as much solar energy as all of the know oil and gas reserves in he world). Wells in the northeast are not often able to provide the high flow rates as required to utilize this beneficial method – and often a return or diffusion well is not practical. Under local or State environmental controls, return has been allowed to surface waters owned by the user. The geology south of Plymouth MA and Long Island NY can lend itself to this advantageous method.

A Standing Column Well system depends upon near-surface bedrock, this is defined as bedrock being within 150-200 feet of the surface. The bedrock provides enhanced heat transfer and requirement for costly steel/plastic casing to keep the borehole open in the “overburden” above the stable bed rock. Approximately 65% of the U.S. meets this criteria and approximately 80% of the northeast qualifies. The geothermal designer must know the rock types and densities and heat transfer characteristics of the rock.

Closed Loops, in a likewise manner, the designer must know the earth or rock types, moisture content and thermal characteristics of each to design an effective earth coupling method. Non-biodegradable plastic piping and earth coupling grouts are utilized in this earth coupling method. Non-toxic antifreezes and antifreeze additives must be employed in the plastic loops to prevent heat pump heat exchanger or loop freezing during winter operation.

MAINTENANCE

Each of the three methods should check their “liquids” every 1 ½ to 2 years.

The Open Systems and Standing Column Well systems are often employed in conjunction with domestic water systems and should be maintained in a sterile state at all times. Any open well system, whether used for a heat pump or only domestic, should be free of harmful bacteria (e.g. fecal coliform) should be checked periodically. Iron bacterial (e.g. ganlionella) is not harmful to humans and is often man-induced. The iron bacterium causes “red-brown” deposits in toilet bowels and in pipes. If the deposits are not controlled, pipes can eventually become occluded. Geothermal heat pump heat exchangers are not effected, as they are copper-nickel alloy and are heated well above bacterial killing temperatures (>130°F) during air conditioning periods.

Closed Loop systems can develop oxygen entrainment and can react with the antifreeze solutions and their additives to develop and acid concentration. These are easily checked with litmus or other pH evaluation methods. Some closed loop systems have automatic make-up water devices in the event the loop should develop a leak. These systems must be periodically verified for proper antifreeze concentration and pH (Acid activity).

REGULATORY

Open to recycle to geothermal earth systems have been in the northeast for over 60 years and as a result have been the most regulated. Our oldest knowledge is a geothermal well water system in New Haven CT, installed in 1938. For Open to recycle and Standing Column Well systems, Federal and related State regulations involve permitting of water withdrawal, and responsible return of the water to the earth. Other regulations may apply to excessive withdrawal, return to navigable streams or rivers and other activities that may impact the water supply or quality.

Closed Loop systems designs are more recent, only being listed and evaluated by the Air Conditioning and Refrigeration Institute (ARI), since 1988 (ARI 330). Most States are now starting to develop regulations on these systems. With some states still having no regulations relating to these earth coupling methods. Typical regulatory requirements include, certification of loop installers, abandonment plan filings, listing of antifreeze solution compounds including additives, and mapping of loop fields.

THERMAL STABILITY

Open to recycle systems are by definition thermally stable over a multiple year period. As the ground water at a constant temperature is employed and “new” thermally consistent water is employed there is no thermal change in the subsurface geology.

Standing Column Well systems change the earth temperature in a cylinder about the well column on an annual basis. The thermal effect is typically depleted 40-50 feet from the borehole column. Ten plus years of field tests have shown no annual change in the mean earth temperature in properly designed and implemented Standing Column Well systems. Should a Standing Column Well manifest a trend away from the mean earth temperature a small advective “bleed” or over flow (5%-10%) results in the rapid re-stabilization of the bore temperature, i.e. increased in winter and decreased in summer.

Proper design must recognize geologic thermal characteristics, relative heating and cooling loads and adequate spacing of multipleStanding Column Wells. A standing column well can be up to 1,500 feet deep and develop 30 –43 tons of capacity. A 350-foot deep domestic use Standing Column Well can develop approximately 5 tons of heat transfer.

Typical spacing is 50-75 feet for multiple Standing Column Wells. Closer spacing can reduce bore hole heat transfer due to thermal interference between bores. Design compensation is necessary when faced with closer spacings.

Close Loop Systems do not have the ability to “bleed” or otherwise introduce fresh water into the loop bores to re-stabilize the earth temperature surrounding the plastic loops. As such, the closed loops are then most sensitive to annual thermal effects. Absolute annual earth moisture minimums must be considered and will impact responsible closed loop designs. Field test have shown long term earth temperature increases in commercial installations.

Typical spacing of closed vertical loops are 15-20 feet apart with 6-inch bores with, 300–450 foot depths, providing 1 ½ to 2 ½ tons per bore hole. Closed loop bores are often grouted with bacteria free Bentonite clay or other type grouts to enhance heat transfer to the earth